Scoobynut

Member

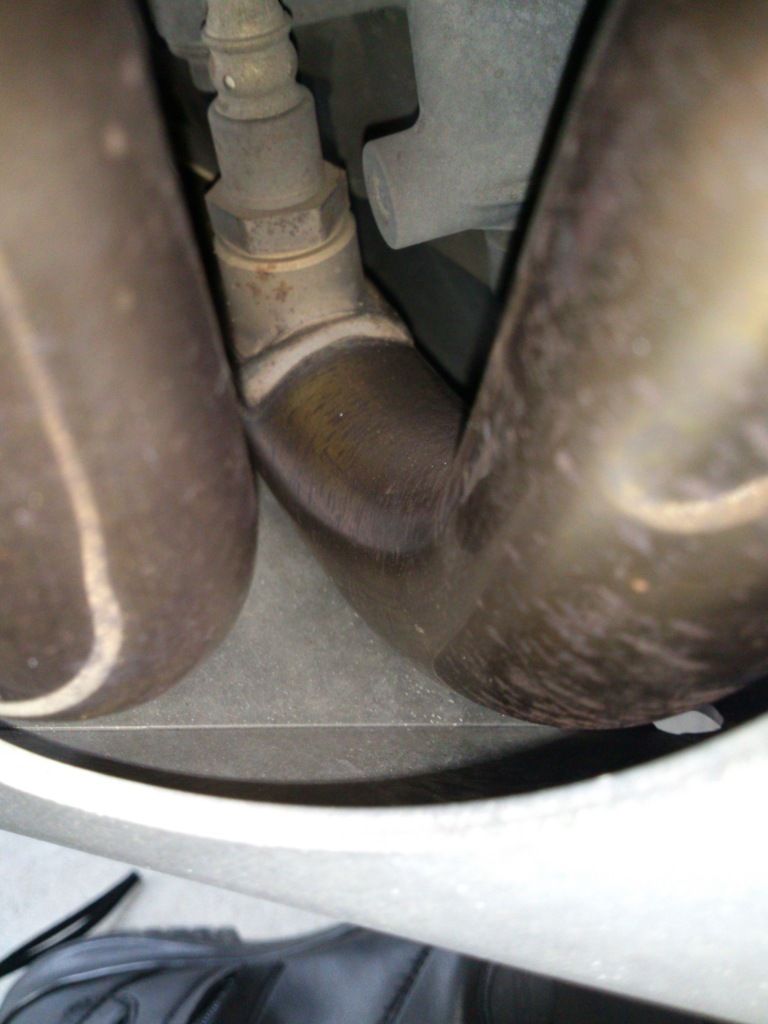

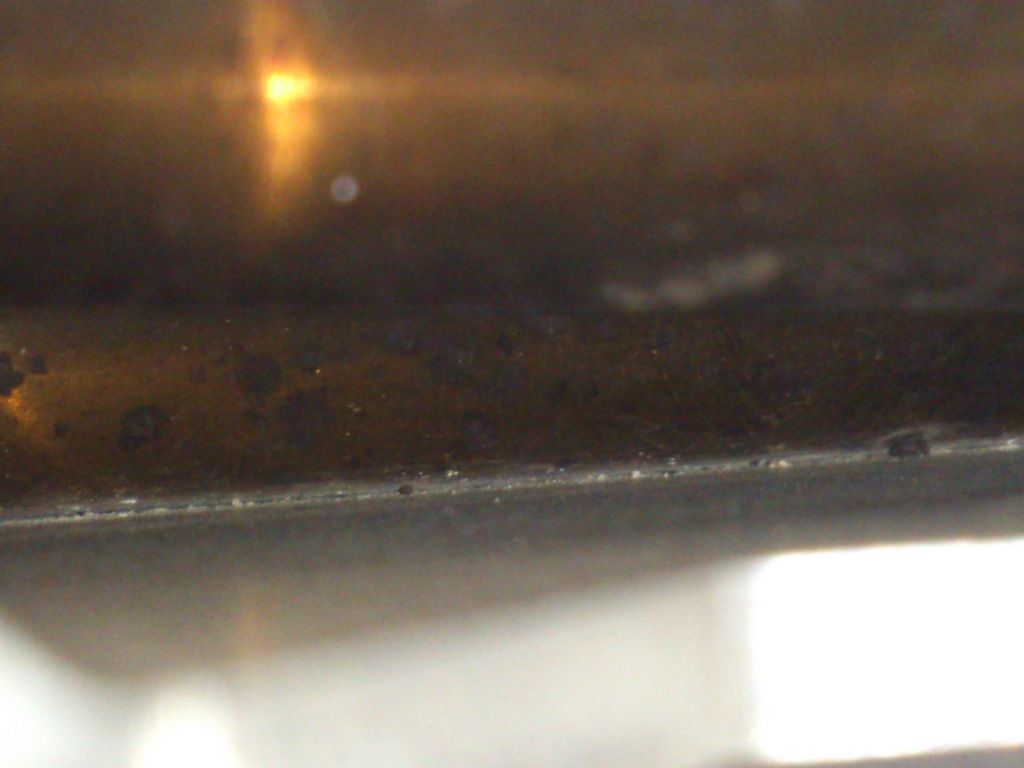

I haven't seen anyone else comment on this, so I thought I'd ask if anyone using the H-B skidplate has changed their oil and noticed any markings on the skidplate from where it's contacting the header. When I last changed my oil a little while ago, I cleaned the inside of the skidplate, and while cleaning it, I noticed a mark or scuffing about 2" long from the lowest-hanging part of the two header pipes (it's only contacting one of the header pipes). It's only contacting the skidplate in that 2" area, but in looking at a similar length marking on the header, the skidplate is definitely touching the exhaust in that one place. I have two concerns about this. 1.) It's definitely creating a hollow, high pitched resonance at certain rpms. Not the end of the world, but knowing it's because the skidplate is touching the header bothers me as you would expect. 2.) If it's touching as described, if the skidplate gets compressed at all from hitting a rock or other object, it's probably gonna crunch that head pipe and possibly cause other damage at the flange where it enters the motor.

I've checked all the brackets for tightness and alignment and they are installed as they should be as far as I can tell -- as a matter of fact, any small adjustments I've made to the rear and/or front bracket to try to lower the skidplate a slight amount has only resulted in an inability to get the bolts to line up to the threads of the brackets, so it seems that either the brackets I have are a little out of spec, or possibly they're all like that, but no one else has noticed this clearance issue when changing their oil. Unfortunately, I didn't take a picture of the scuff on the plate or the header when I had the skiplate off. Anyone care to chime in on this? All thoughts and ideas welcome.

I've checked all the brackets for tightness and alignment and they are installed as they should be as far as I can tell -- as a matter of fact, any small adjustments I've made to the rear and/or front bracket to try to lower the skidplate a slight amount has only resulted in an inability to get the bolts to line up to the threads of the brackets, so it seems that either the brackets I have are a little out of spec, or possibly they're all like that, but no one else has noticed this clearance issue when changing their oil. Unfortunately, I didn't take a picture of the scuff on the plate or the header when I had the skiplate off. Anyone care to chime in on this? All thoughts and ideas welcome.