Thanks Krabill. I enjoy working with your brother because we share the same riding passion. I have actually ridden the bike to Tulsa from here in Orlando 3 times this year for business trips and I have to go back in Late October. I sure hope I have the bike back together by then or I will have to fly.

Those darn airplanes are unsafe!

We should get together then and compare notes.

Well here is the current state of the bike. The motor is sitting on a floor jack, still loosely in the motor mounts but all bolts and attachments removed and ready to drop:

Now what is making me nervous is, how I am going to lower it without it falling over. I expect it is around 200 LB and I am by myself. So I hit the pause button to think on it a bit. Any Ideas?

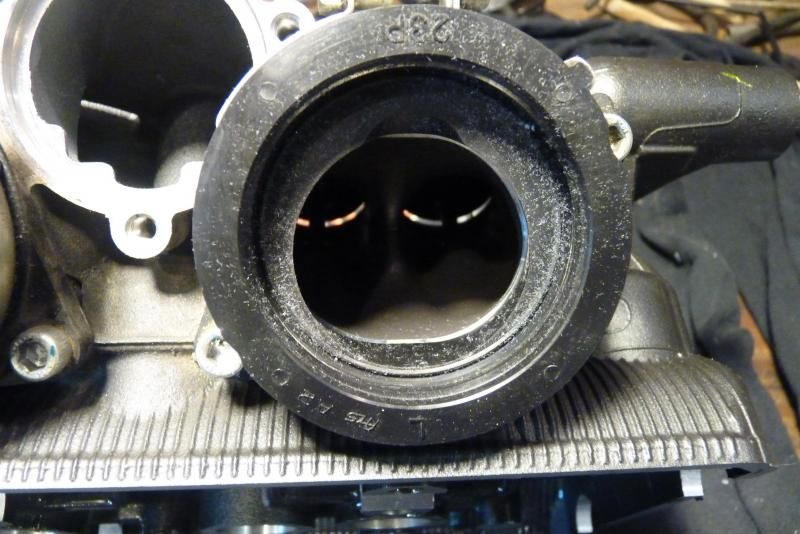

It is hard to see in this photo bu the intake guide is bent and twisted. ???

I believe what happen is that when I installed the intake cam and timing chain, I somehow got the guide out of align and when I released the tensioner and it popped in, it somehow slipped by the bent and/or out of place tensioner and allowed the nose of the tensioner plunger to directly contact the chain. That actually worked for awhile (50 miles or so) until the tip of the plunger got warn down and the plunger shortened to the point that it got pushed completely out of the tensioner body.

It is so tight in there that it is hard to imagine how the plunger could have gotten around the guide. And it looked fine from the bottom when I released the plunger. But I can see no other explanation and the wear pattern on the nose of the plunger clearly indicates prolonged contact with the chain.

I sure am glad that this time I will be able to install the cams and chain with the engine out so I can see much better and make sure all is well before I button it up.

I fear the next "nightmare" may be getting ALL the required parts as even one key part out of stock will bring things to a stop.

More to come.

John

They both look fine as far as I can see from looking down or looking up from the bottom. I will look tonight to see if I can get them out. And yes they seem conventional. The intake side does have a retainer at the bottom but it looks like it is just a pivot pin with a small plate bolted over the top. If it looks like a PIA to get them out I will wait until I have the motor out.