I made the mistake of putting something on the stock plastic crappy rack and it broke off. Altrider rack is $318 in Canada so not happening f@ck you very much Altrider. First I tried a wooden one because I can't weld aluminum and thought it would be worth a try. It worked really well and was solid but I couldn't get onboard (pun intended) with wood.

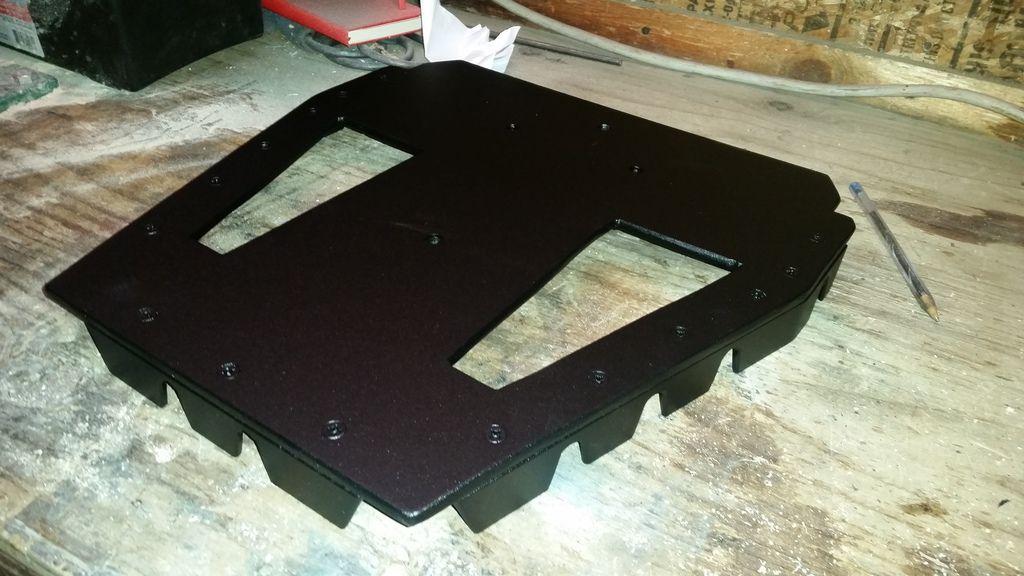

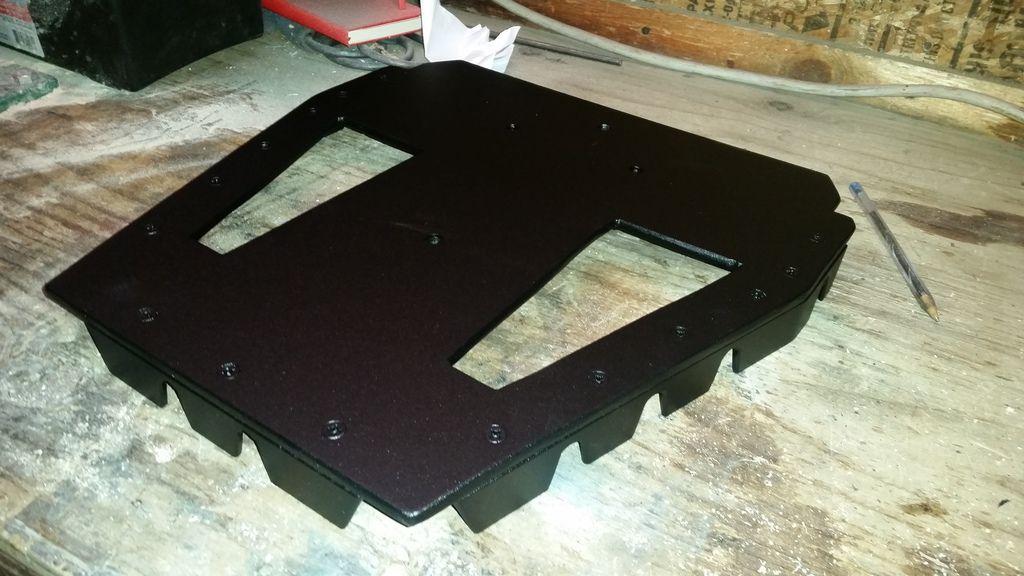

I decide to put the rear seat back on and had trouble getting along with the back rest so aluminum was back in play. I made one for around $80, $65 of that was powder coating. All hand tools except for using my miter saw to cut the aluminum. Miter saw worked amazingly well btw. And no welding.

I decide to put the rear seat back on and had trouble getting along with the back rest so aluminum was back in play. I made one for around $80, $65 of that was powder coating. All hand tools except for using my miter saw to cut the aluminum. Miter saw worked amazingly well btw. And no welding.