Anybody recommend a set of feeler gauges for the valve check. Looking for a set with very small increments. All the sets I own or see locally make some big jumps and want to really get a near perfect measurement.

Feeler gauges

- Thread starter becoyote

- Start date

Koinz

Active Member

Founding Member

2011 Site Supporter

2012 Site Supporter

2013 Site Supporter

2014 Site Supporter

I have a few sets. As long as they're between .002" and .012" I don't think I've used them for anything greater. Any car parts outlet has them. I noticed the Autozone description might be wrong.

Description says the're in inches, but the number range makes more sense if they're in mm.

Near Perfect to me means they're in the spec range, so if one is .001 - .002 difference, that's perfect for me.

They're going to change and maybe not at the same rate so to get them all the same is an exercise in futility.

Description says the're in inches, but the number range makes more sense if they're in mm.

Near Perfect to me means they're in the spec range, so if one is .001 - .002 difference, that's perfect for me.

They're going to change and maybe not at the same rate so to get them all the same is an exercise in futility.

If you're really trying to be precise, I'd get a metric set. There are some significant round-off errors when you take clearances spec'ed in metric, convert them to english (thousands), use english feeler gauges for measurement, then start trying to convert back to metric to spec which metric-based shim to use.

Having said this, I echo the previous comment about trying for "near perfect measurement". The increment between shims is more than half the acceptable range of clearances so, more often than not, there is no fine-tuning of clearances - if a clearance is out of spec, you swap with a new one and accept where ever it lands in the acceptable range.

- Mark

Having said this, I echo the previous comment about trying for "near perfect measurement". The increment between shims is more than half the acceptable range of clearances so, more often than not, there is no fine-tuning of clearances - if a clearance is out of spec, you swap with a new one and accept where ever it lands in the acceptable range.

- Mark

Don in Lodi

Well-Known Member

Founding Member

2012 Site Supporter

2013 Site Supporter

2014 Site Supporter

Back when I did my Royal Star, some of the shims in the bike were what I came to call half shims, the numbers were somewhere in between what you could go and buy. Yep, you can only get close to perfect. Ere on the wide side, overhead valve trains tighten up as they wear. If you're at the auto parts store looking at feeler gauges, go for the one with a bazzilion feelers. Some only have ten or fifteen, some have thirty or forty.

Thanks all, I ordered a set from McMaster Carr. 26 gauges in .001" increments. Couldn't find an equivalent metric set. Also probably find a source for smaller increment shims this time around. My hot cam set is in .05mm increments

If the gauge is in .001"/.0254mm increments and the shims are in .05mm increments

Intake clearance is between .10 and .16mm

Ex. .22 and .28mm

Seems that with the possible error in the reading and having to make .05 jumps it would be pretty difficult to get them all right where you would want them when there is only .06mm difference between tight and loose.

If the gauge is in .001"/.0254mm increments and the shims are in .05mm increments

Intake clearance is between .10 and .16mm

Ex. .22 and .28mm

Seems that with the possible error in the reading and having to make .05 jumps it would be pretty difficult to get them all right where you would want them when there is only .06mm difference between tight and loose.

Koinz

Active Member

Founding Member

2011 Site Supporter

2012 Site Supporter

2013 Site Supporter

2014 Site Supporter

Yep

.003-.006 intake

.008 - .011 exhaust

I typically like to be in the middle to high side.

I recently had to adjust my new project bike klr valves and I couldn't get a feeler gauge small enough to slide under the lobe on the intakes. So I called it .000" and calculated my shim size from there. I went from a 2.60 to 2.30mm size shim to get in the ball park. That's .010" difference to get to a .005" clearance. I don't think the valves were ever adjusted on it.

You must be good at getting to the valves given your past troubleshooting experience though.

.003-.006 intake

.008 - .011 exhaust

I typically like to be in the middle to high side.

I recently had to adjust my new project bike klr valves and I couldn't get a feeler gauge small enough to slide under the lobe on the intakes. So I called it .000" and calculated my shim size from there. I went from a 2.60 to 2.30mm size shim to get in the ball park. That's .010" difference to get to a .005" clearance. I don't think the valves were ever adjusted on it.

You must be good at getting to the valves given your past troubleshooting experience though.

Bike is at 54k and hopefully it will be my last time unless I keep it to 100k. I plan to skip the next one unless the bike seems off.Koinz said:You must be good at getting to the valves given your past troubleshooting experience though.

Thinking of doing the manual cam chain tensioner now too. I put in a 14 oem cct about 6k ago but it still seems noisy to me.

Exactly. This is why you seldom have any flexibility to decide whether you want to be on the loose side or tight side of spec - if a valve is out of spec, there is only one shim that will bring it back to spec and you won't have any ability to put it on the loose side or the tight side.becoyote said:Seems that with the possible error in the reading and having to make .05 jumps it would be pretty difficult to get them all right where you would want them when there is only .06mm difference between tight and loose.

From the factory, you'll find that installed shims may be in finer than .05mm increments (e.g. a "178" for a 1.78mm shim), but all you can get from Yamaha are .05 increment (e.g., 175 or 180) shims. Perhaps after-market shim kits have smaller increments. Some folks hand sand shims to a desired thickness measured with a micrometer, but I wouldn't be comfortable doing this.

Given how many S10 engines seem to run fine for tens of thousands of miles with no valve checks whatsoever, I doubt the precise clearance matters very much. It's a good idea to have it within the spec'ed range, but I'm sure there is some tolerance that it can be outside it a bit without dire harm. As long as the valve has some working clearance when hot, the engine should run fine. Laboring over getting the valve clearances as perfect as you can get them doesn't seem worth the effort to me. The spec'ed range is plenty "good enough".

- Mark

caillou

New Member

I agree. And I have the same approach for torque wrench. Not that precision is as critical as feeler gauge, but to avoid mistakes or bad conversion (that you find also in Clymer and Haynes BTW).markjenn said:If you're really trying to be precise, I'd get a metric set. There are some significant round-off errors when you take clearances spec'ed in metric, convert them to english (thousands), use english feeler gauges for measurement, then start trying to convert back to metric to spec which metric-based shim to use.

- Mark

Gigitt

Active Member

There are aftermarket shim suppliers - there has to be!

If we have a local bloke in Melbourne Australia making shims with .02mm increments - State side should!

You just have to find them.

Not affiliated but I used them when I did my Versys 650

http://www.precisionshims.com.au/

If we have a local bloke in Melbourne Australia making shims with .02mm increments - State side should!

You just have to find them.

Not affiliated but I used them when I did my Versys 650

http://www.precisionshims.com.au/

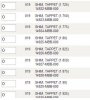

You can use Honda TRX 450R shims(9.48mm) they come in .025 increments. Hot Cams shows the Yamaha and Honda shims to be th same.markjenn said:Exactly. This is why you seldom have any flexibility to decide whether you want to be on the loose side or tight side of spec - if a valve is out of spec, there is only one shim that will bring it back to spec and you won't have any ability to put it on the loose side or the tight side.

From the factory, you'll find that installed shims may be in finer than .05mm increments (e.g. a "178" for a 1.78mm shim), but all you can get from Yamaha are .05 increment (e.g., 175 or 180) shims. Perhaps after-market shim kits have smaller increments. Some folks hand sand shims to a desired thickness measured with a micrometer, but I wouldn't be comfortable doing this.

- Mark

Attachments

-

41.5 KB Views: 20

Thanks all. I was just coming back to post about the Honda shims.